News & Knowledge

Pre-Printing Tips

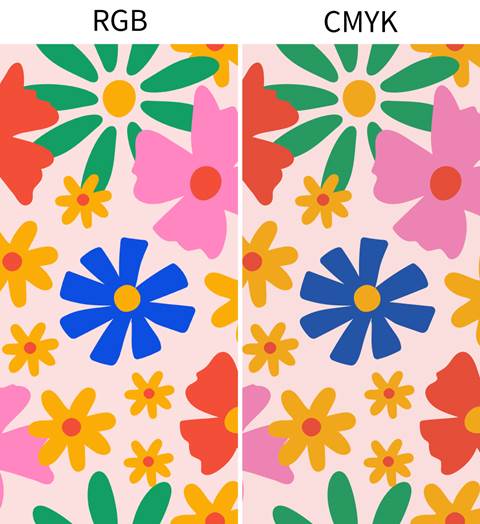

The colors used in printing and those displayed on screens are based on different principles. Therefore, there are some important considerations when creating print files. Here are the differences explained to you: RGB is used for electronic displays, while CMYK is used for printing.

When transitioning from computer screens to print, we must convert images from one color model to another. This file often requires additional processing and can lead to some color differences. Therefore, when creating print files, it is recommended to set the color mode to CMYK from the beginning.

Table of Contents

ToggleRGB vs. CMYK

RGB Stands for Red, Green, and Blue. This color model is used for electronic displays such as computer screens and TVs. RGB is an “additive color model,” creating various colors by mixing red, green, and blue light proportions. When all three colors are mixed, white light is produced; when no light is present, the result is black.

CMYK Stands for Cyan, Magenta, Yellow, and Black (Key). CMYK is a “subtractive color model” mainly used in printing. It creates colors by subtracting light from white paper. For instance, cyan absorbs red light, magenta absorbs green light, and yellow absorbs blue light. Black (K) is used to provide depth and contrast.

Possible Issues When Converting RGB to CMYK

The conversion from RGB to CMYK can lead to color changes and issues, mainly because RGB and CMYK are two different color models. They have fundamental differences, including various color gamuts and color mixing methods.

Common Issues

Color Gamut Differences:

RGB and CMYK have different color gamuts, which can represent different ranges of colors. RGB has a broader gamut, especially for screen displays. Therefore, when RGB images are converted to CMYK, some colors may fall outside the CMYK gamut, resulting in color distortion or inaccuracy.

Color Distortion:

Because RGB and CMYK use different principles to represent colors, some cannot be accurately converted.

For example, certain vibrant fluorescent colors or specific bright reds cannot be precisely represented in CMYK, as they fall outside the CMYK color gamut.

Detail Loss:

Subtle color details may be lost during conversion, especially in overly saturated or profound color areas. This color can lead to losing some details or reducing color smoothness.

Black Conversion:

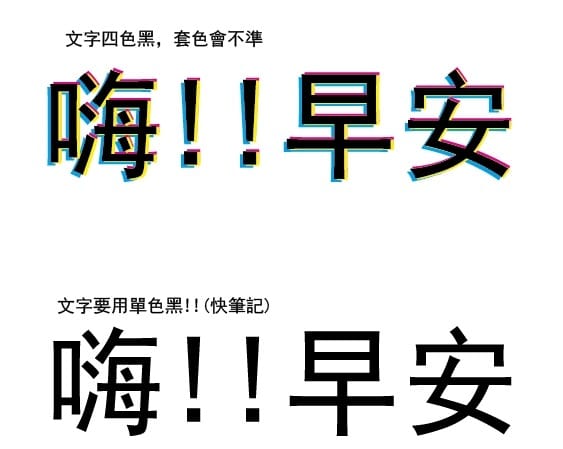

In RGB, black is the pure absence of light. In CMYK, black is created by mixing cyan, magenta, and yellow. Therefore, during the conversion process, the representation of black can be affected, resulting in different black densities and color combinations.

How to convert RGB to CMYK to minimize errors

Set the document to CMYK mode & convert four-color black to single-color black:

Ensure that the color management settings in your image editing software are correct, including ensuring that the color settings and file format support CMYK color mode. Do not use four-color black; convert four-color black to single-color black. Adjust the K value density (percentage) if gray tones are needed.

Preview and Compare:

After the conversion, preview the RGB and CMYK versions of the image and compare the differences between them. This will help you understand any color changes and issues arising during the conversion process and allow you to make immediate adjustments.

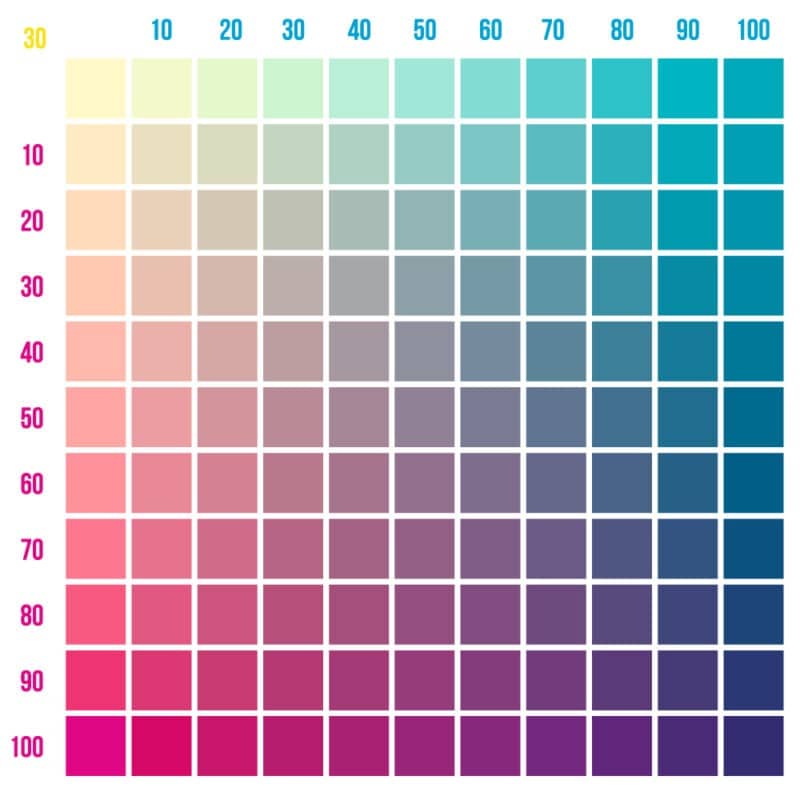

Use a Color Guide:

Refer to the information in the color guide to reduce the difference between design and print colors.

In image processing, this refers to the range of all colors represented in a color space. Using a color guide mainly involves understanding and utilizing the concept of the color gamut and the corresponding tools to ensure that the colors of the image are consistently and accurately presented on different devices and media.

Common NG Finalization Issues

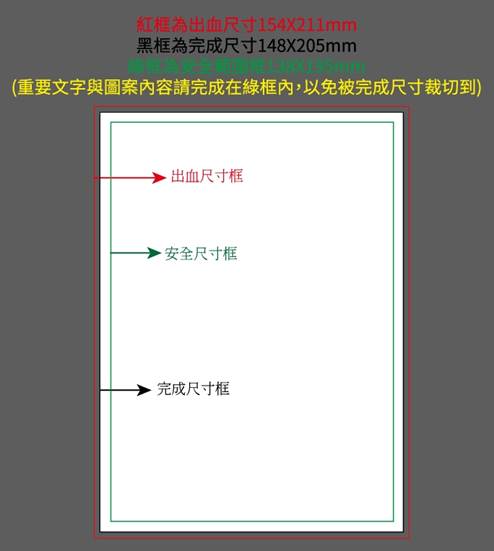

No Bleed Setting :

After printing, cutting may result in white edges or the removal of the main content. Therefore, the size should be set with a 3mm bleed on all four sides from the beginning.

Workspace Setting :

Standard Error -> Workspace size = enlarged size after a bleed

Correct Setting -> Workspace size = final size, with bleed set separately.

Safe Margin :

All text should be moved 0.5 cm inward from the final size. Folding and cutting have tolerances, so if the text is too close to the edge, it may get cut off.

Four-Color Black:

Black composed of CMYK can cause misregistration issues during printing. The correct method is to convert it to single-color black/gray.

Setoff :

If the ink is not thoroughly dried, it can be transferred from the back to the front of the sheets. If the total CMYK value exceeds 250%, it can cause the ink to dry slowly, leading to setoff when stacking during printing. Ensure all values do not exceed 250% before sending to print.

Colors That Are Most Difficult to Print

The most difficult colors in printing are usually metallic, fluorescent, and mid-tones.

These colors require special inks or more technical experience and expertise to ensure the quality and accuracy of the final printed product.

For example :

Metallic Colors :

Metallic pigments or unique ink formulations are required to achieve a metallic texture.

Fluorescent Colors:

High-brightness pigments are needed to produce a vibrant effect.

Mid-Tones :

It requires precise blending and layering of different color inks to achieve the desired color effect.

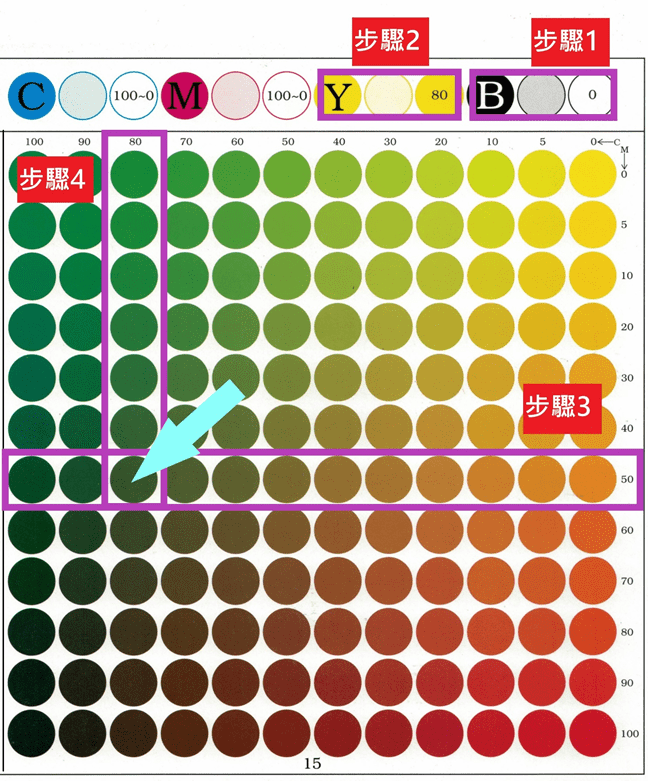

How to Use a Color Guide in Four Steps

Using C80 M50 Y80 K0 as an example

Check sequence: KYMC (Tip: Check in reverse order)

Step 1 :

Find the page with a K value of 0 in the table header.

Step 2 :

Find the page with a Y value of 80 in the table header.

Step 3 :

Move up and down to find the row with an M value of 50.

Step 4 :

Move left and right to find the column with a C value 80.

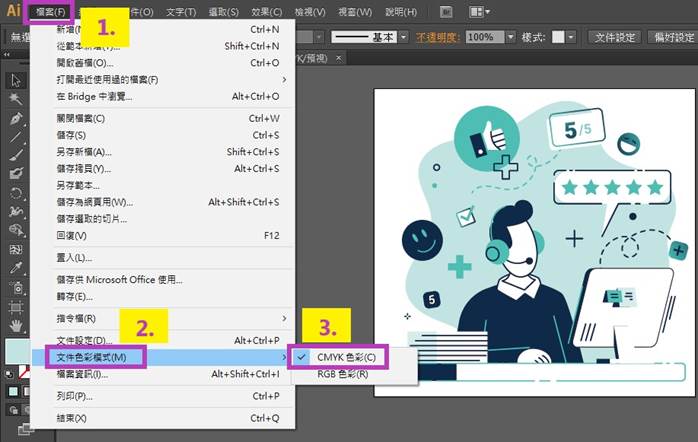

How to Convert RGB to CMYK in Three Steps

- Select “File.”

- Choose “Document Color Mode”

- Check “CMYK Color”

Knowledge of Gang Run Printing

Gang-run printing, as the name suggests, combines your print job with others on the same print sheet. This printing method is suitable for small print runs.

Since the print sheet is shared with other jobs, there can be color variations, typically around 10-20%, even within the same batch.

The variations mainly depend on the colors used in the combined print jobs.

For example, if the print sheet has more blue jobs, the overall print may have a blue tint.

If the print sheet has more yellow jobs, the overall print may have a yellow tint.