News & Knowledge

Common Printing Units and Paper Terminology

What is four-color printing? What does “unit” mean? Many commonly used units and professional terms can often be confusing during the printing and binding process. Below are the standard units and terms used in the industry, helping you understand how to communicate with manufacturers to produce your printed materials ideally.

Table of Contents

ToggleMost Common Units of Measurement in Printing

In the printing world, precision is key. Whether you are a graphic designer, publisher, or simply curious, knowing how measurements work in printing can help you communicate clearly and avoid costly mistakes.

Here are the most common printing measurement units:

| Unit | Abbreviation | Equivalent | Usage |

|---|---|---|---|

| Point | pt | 1 pt = 1/72 inch | Font size, line spacing |

| Pica | pc | 1 pc = 12 pt = 1/6 inch | Layout & column width |

| Inch | in | Imperial system | U.S. standard paper sizes |

| Millimeter | mm | Metric system | International sizing |

| Pixel | px | Digital screen unit | Web design only |

🔍 Example: 12 pt font size = 1 pica = 1/6 inch.

Paper Size Standards (U.S. vs International)

Paper dimensions vary around the world. Here’s a quick comparison between U.S. and ISO (International) standards:

📋 U.S. Standard Paper Sizes (in inches)

| Name | Size (in) | Common Uses |

| Letter | 8.5 × 11 | Everyday documents, notebooks |

| Legal | 8.5 × 14 | Contracts, legal paperwork |

| Tabloid | 11 × 17 | Posters, folded brochures |

📐 ISO Paper Sizes (A Series, in mm)

| Name | Size (mm) | Uses |

| A4 | 210 × 297 | Standard global documents |

| A5 | 148 × 210 | Planners, notebooks |

| A6 | 105 × 148 | Pocket diaries, cards |

Printing Units Conversion Chart

Quick Conversion: Inches ↔ Millimeters ↔ Points

| Measurement | Inches | Millimeters | Points |

| 1 inch | 1 in | 25.4 mm | 72 pt |

| 1 mm | 0.039 in | 1 mm | 2.83 pt |

| 1 pt | 0.0139 in | 0.3528 mm | 1 pt |

✅ Handy when converting between digital files and physical prints.

Glossary of Common Printing Terms

A short list of must-know terms for print production:

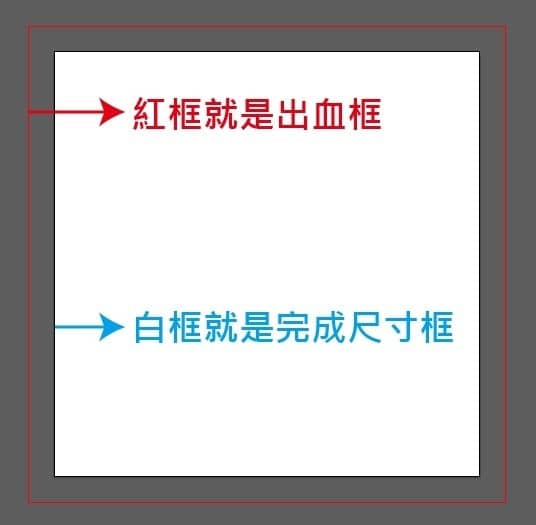

- Bleed – Extra image area extending beyond trim lines.

- Crop Marks – Lines that show where the page should be cut.

- CMYK – Cyan, Magenta, Yellow, and Black; used in color printing.

- GSM – Grams per square meter; indicates paper weight.

- Perfect Binding – A bookbinding method using glue.

- Saddle Stitching – Stapled booklets or magazines.

- Spot UV – Glossy coating applied to a specific area.

Fun Fact – Why Are These Terms in Crossword Clues?

Many of the terms we use in printing—like “pica,” “point,” or “gsm”—are so unique and standardized that they often appear in crossword puzzles. If you’ve searched for:

-

“Printing measures crossword clue”

-

“Unit of paper 4 letters”

-

“Printer measure 3 letters”

You’re not alone! These phrases bring a lot of curious visitors to our page. And yes—the answer is often “pica” or “gsm”!

Common Printing Units and Professional Terminology

-

Point (pt)

Definition: A point is a unit of measurement commonly used for font sizes. One inch equals 72 points.

Usage: Font sizes, line spacing, and spacing in layout design are typically measured in points. -

Inch (in)

Definition: In the imperial and US customary systems, an inch is a unit of length equal to 1/12 of a foot, approximately 2.54 centimeters. It measures the width, height, and margins of print materials.

Usage: The dimensions of print materials are often measured in inches; for example, the standard size of a Letter paper is 8.5 x 11 inches. -

Centimeter (cm)

Definition: A centimeter is a unit of length in the metric system, equal to one-hundredth of a meter. It is a standard unit of size larger than a millimeter in the metric system.

Usage: It is widely used in Adobe Illustrator to measure print object dimensions. -

Millimeter (mm)

Definition: A millimeter is a metric unit of length equal to one-thousandth of a meter.

Usage: Extensively used in Adobe Illustrator for dimensions of print objects, as it is the smallest unit of length and more suitable for arranging small-sized designs than other units. -

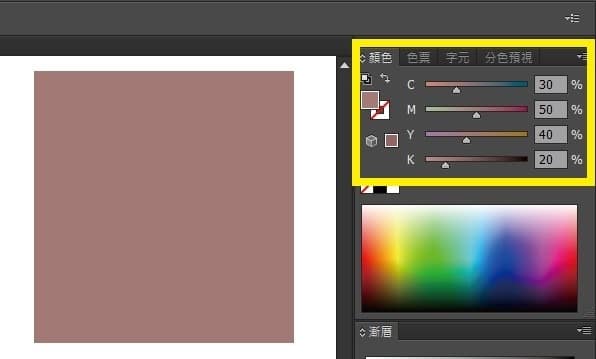

CMYK

Definition: CMYK stands for Cyan, Magenta, Yellow, and Key (black), a color mode setting in printing.

Usage: All colors in printing are composed and adjusted using CMYK values to create various hues.

-

Trim Size

Definition: The final cut size of a printed item, representing the size of the finished product.

Usage: Designers must determine the trim size in the printing design process to ensure that layouts and images are correctly positioned in the final printed product.

-

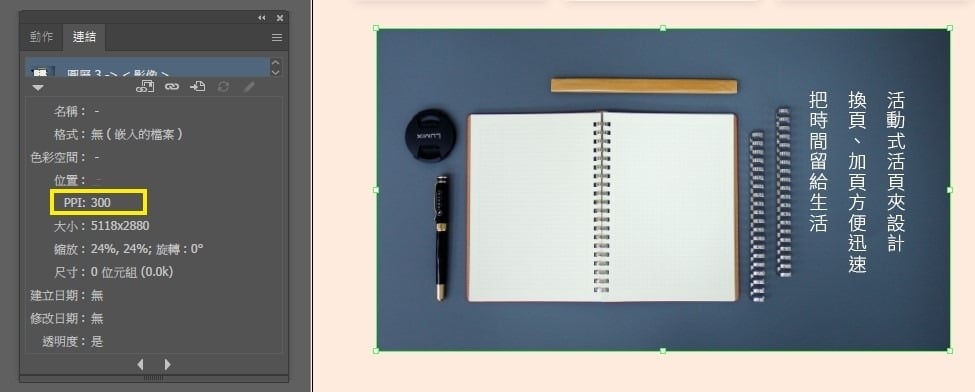

DPI(Dots Per Inch)

Definition: DPI is a term used in printing and scanning to indicate the density of dots per inch. It measures the number of dots within one inch of the print and is generally associated with print quality.

Usage: In the printing industry, DPI describes a print’s resolution, that is, the number of printing dots per inch. Generally, a higher DPI indicates higher print quality because more dots are used to render an image, making it more detailed.

-

PPI(Pixels Per Inch)

Definition: PPI primarily applies to digital images and denotes the pixel density per inch.

Usage: In web design, PPI is important because it determines how an image appears on screen. A higher PPI usually means a finer image detail, while a lower PPI might display a grainy appearance.

Standard Units and Professional Terms for Paper

In the printing and publishing fields, paper sizes are often represented using standardized units, detailed below:

-

A Series

The A series is a standard set of paper sizes established by the international standard ISO, with A0 being the largest and decreasing sequentially through A1, A2, A3, A4, etc. Each size is half the size of the one before it. For instance, A4 is half the size of A3, and A5 is half that of A4. A series of sizes, such as A4 and A5, are commonly used for printing documents, books, manuals, and magazines.

-

B Series

Like the A series, the B series is based on ISO standards, starting with B0 as the largest size and decreasing with B1, B2, B3, B4, etc. This series provides average sizes between the A series sizes, making layout and printing more convenient. The B series is commonly used for posters, fine art papers, and commercial advertisements. B5, for instance, is a standard print paper size.

-

C Series

The C series is predominantly used for making envelopes corresponding to A series paper sizes. For example, if the paper size is A4, a C4-size envelope would be appropriate; if the paper is folded in half to A5 size, a C5 envelope would be used.

-

One Sheet

Definition: A sheet of paper has two sides, front and back. If a book contains 80 sheets, it would have 160 pages.

-

One Page

Definition: Typically refers to a page in a book or document pointing to a designated page and, for example, turning to page 64 in a textbook.

-

One Side

Definition: Generally refers to one side of a sheet of paper, used to describe the layout of a print product. It can also be synonymous with “page.” For example, page 2 = side 2.

-

One Strip

Definition: A strip is a unit of measurement used to gauge the thickness of paper or in precision measuring tools. One Strip equals 0.01mm, and a typical 80g offset paper sheet is about 9.5 strips thick.

-

One Bundle

Definition: A packaging unit for flat sheets of paper, varying in number of sheets depending on the thickness of the paper, typically 100, 200, or 300 sheets per Bundle.

-

One Ream

Definition: Typically refers to a quantity of 500 sheets of flat paper. One Ream equals 500 sheets.

-

One Box

Definition: Commonly refers to the packaging of business cards. One Box usually contains about 100 cards.

-

One Thousand Runs

Definition: In the printing industry, a term describes the quantity of printed items calculated in thousands. For example, two thousand runs = the same content printed 2,000 times.

-

Four Color

Definition: Refers to the CMYK color printing model. For instance, 1-color printing would use only black (K), 2-color printing would use two-color printing, and so forth.

-

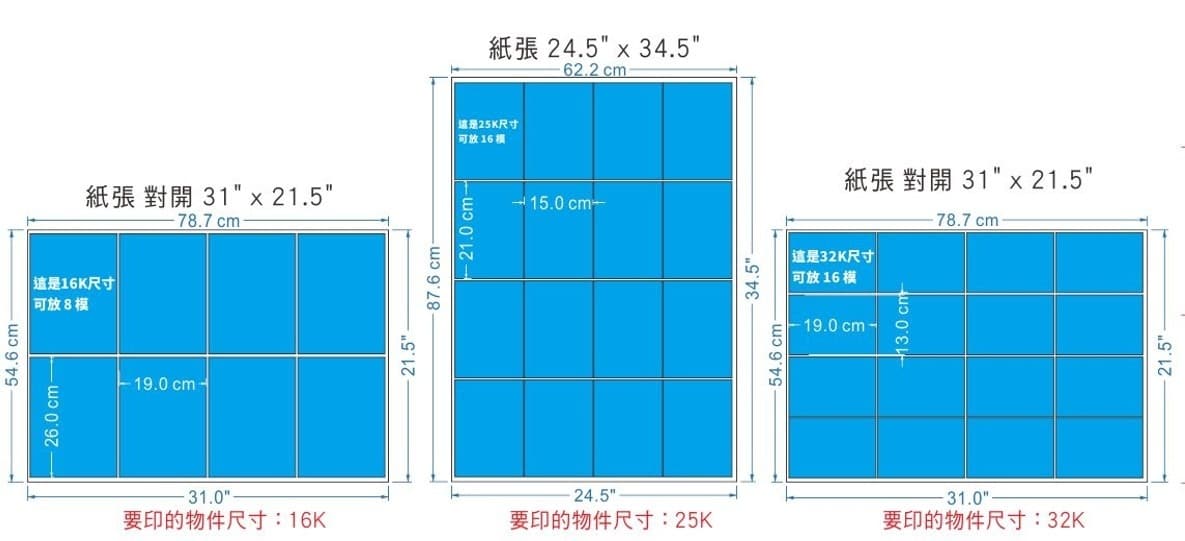

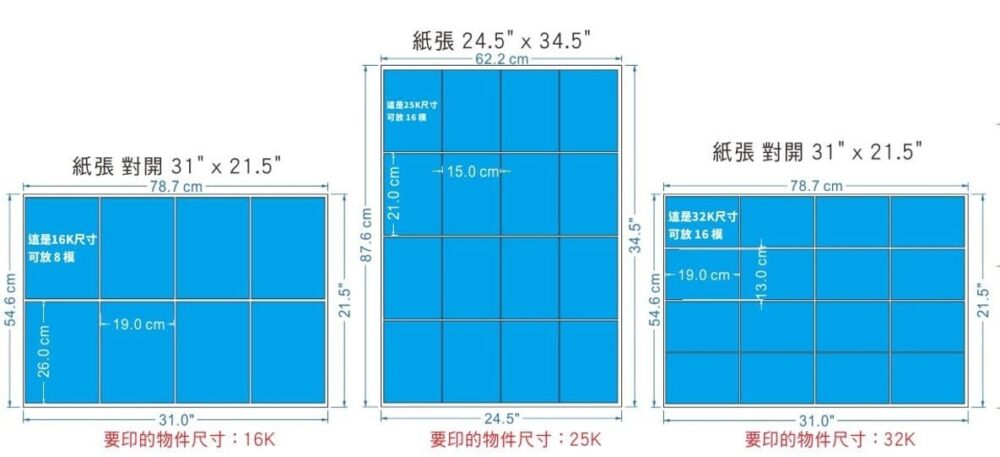

One signature (Printing)

Definition: Refers to printing one large sheet at a time, where the number of impositions(patterns) that can be pieced together varies depending on the size of the large sheet and the printed item.

-

One signature (Binding)

Definition: The paper is folded as one unit after printing on a large size. For an A5 notebook printed on a kikuban size sheet, one unit results in 16 sheets or 32 pages. For a B5 notebook, one unit results in 8 sheets or 16 pages.

Standard Printing and Post-Processing Issues

-

Setoff

Definition: Ink marks appearing on the back of the paper. This may occur due to excessively thick ink or inappropriate paper type.

Solution: Adjust the ink density or use suitable paper. -

Show-through

Definition: Visibility of print from one side of the page to the other, often due to thin paper or inappropriate ink.

Solution: Choose a thicker paper or use appropriate ink. -

Dragging

Definition: Streaks formed by ink during printing are typically caused by printing speed that is too fast, high ink viscosity, or insufficient machinery maintenance.

Solution: Adjust printing speed, use ink of proper viscosity, and regularly clean and maintain the printer. -

Paper Dust

Definition: Small or tiny paper particles in the printing process, usually due to poor paper quality or a dirty printer.

Solution: Use high-quality paper or run the printer without ink to clear debris. If paper dust is severe, request a new batch of paper from the supplier. -

Unevenness

Definition: Uneven distribution of color on the print, possibly due to issues with ink supply, ink settling, or the printing machinery.

Solution: Have a technician inspect the printer or use scrap paper to test until the print quality is even before switching to the final paper. -

Bursting

Definition: Exposure of the paper’s core fiber color when paper with short fibers and high weight is folded during printing.

Solution: Consult the paper manufacturer about the fiber direction before printing to minimize bursting during folding, or suggest pre-molding before folding. -

Mottling

Definition: White areas of the print appear speckled, and the color saturation is uneven.

Solution: Adjust the ink density and uniformity, use scrap paper to test until the print quality is even, then switch to the final paper. -

Graininess

Definition: Irregular, grainy protrusions on a finished print, typically caused by excessive powder spraying during printing.

Solution: Check and clean the printing machine or reduce the amount of spray powder. -

Yellowing

Definition: The printed material turns yellow over time.

Solution: Choose light-resistant, anti-oxidative acid-free paper; store in dry conditions away from sunlight. -

Waviness

Definition: The print exhibits a wavy form, possibly due to excessive glue in the binding that traps moisture.

Solution: Control the moisture content in the glue and keep the material dry. -

Grain Direction

Definition: Fibers align in one direction during papermaking, affecting print quality and adaptability to post-processing.

If misused, it may cause the print’s design or text to appear distorted and affect folding or binding flexibility, like bending, impacting the book’s usability.

Solution: Discuss the paper choice and orientation with the paper supplier or printer before design and printing to ensure the selected grain direction meets the final product’s requirements.

FAQ

Q1: What is the standard unit of measurement in printing?

A: Points (pt) and picas (pc) are commonly used for fonts and layouts. Inches and millimeters are used for paper dimensions.

Q2: What does GSM mean in paper?

A: GSM stands for Grams per Square Meter. It indicates paper thickness and weight.

Q3: What is a pica in typography?

A: A pica equals 12 points or 1/6 inch. It’s used for column and layout measurements.

Q4: Why do I see “printing units crossword clue” in search results?

A: These terms are common answers in crossword puzzles, often referring to “pica,” “gsm,” or “pt.”