News & Knowledge

Differences Between Paperback and Hardcover: What Are the Types of Binding?

Table of Contents

ToggleDifferences Between Paperback and Hardcover? What Are the Types of Binding?

Let’s first understand the methods of bookbinding, which can be divided into adhesive (perfect) binding with or without threads, then extend to the differences between paperback and hardcover.

|

w/o threads |

Paperback |

Traditional perfect binding | ||

| PUR adhesive binding | ||||

|

with threads |

Hardcover |

Flat-back hardcover | ||

| Round-back hardcover | ||||

| Case binding (similar to diploma-style binding) | ||||

|

Paperback |

Standard thread-sewn paperback | |||

| Wide-open thread-sewn paperback | ||||

| Lay-flat thread-sewn paperback | ||||

Whether it’s a paperback or a hardcover, the spine of the inner pages requires adhesive application. Depending on whether the pages are sewn together and the thickness of the adhesive, different types of semi-finished products can be produced. This process is collectively referred to as “perfect binding” and is divided into two types: “threadless perfect binding” and “thread-sewn perfect binding.”

Simply put, it depends on whether there is sewing between the pages. After the pages are sewn, the adhesive on the spine can be thinner, as the thread helps bear the force of page turning. Conversely, threadless perfect binding relies solely on the adhesive’s strength to maintain the structure of the entire volume.

Threadless Perfect Binding: Typically Used for Paperbacks

Threadless Perfect Binding: Typically Used for PaperbacksThis binding method is divided into two types: “Traditional Perfect Binding” and “PUR Binding,” both commonly used for binding books, catalogs, magazines, reference books, and literary novels.

- Traditional Perfect Binding :

This method involves applying a thick layer of hot-melt adhesive to the spine. One drawback is that the book cannot lay flat when opened; it tends to spring back, and forcing it flat can cause the adhesive bond to break, leading to pages detaching. This method is usually used for publications with fewer pages or lighter paper weights, such as catalogs and magazines.

- PUR Binding :

It uses a highly resilient adhesive with solid adhesion, allowing the book to open wider and lay flatter than traditional perfect binding. Due to its superior durability and flexibility, this method is often used for books with more pages, such as literary novels and academic papers.

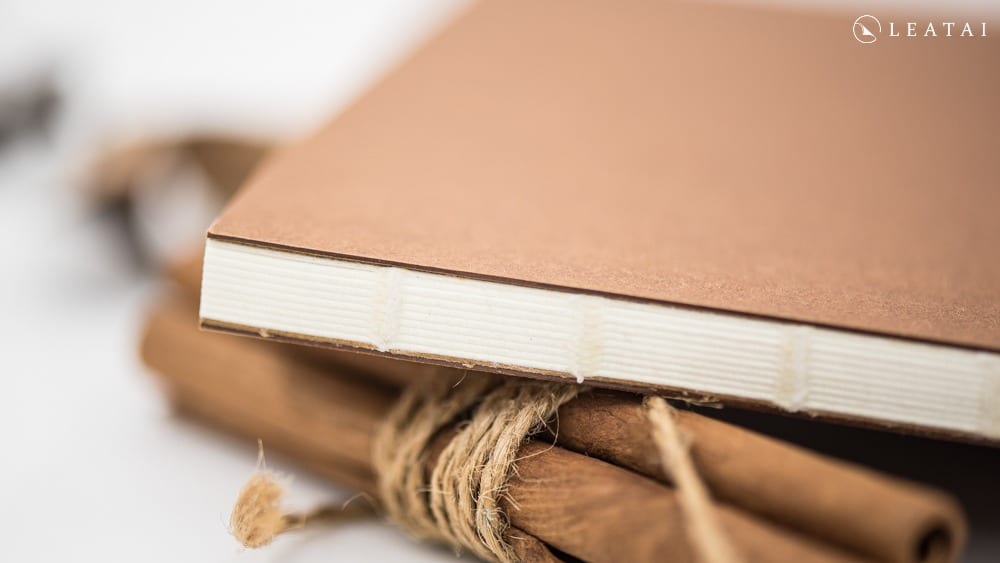

Thread-sewn Perfect Binding: Applicable for Both Paperback and Hardcover Books

Paperback 3 Options: Standard Thread-sewn Paperback, Wide-open Thread-sewn Paperback, Lay-flat Thread-sewn Paperback

Hardcover 3 Options: Square-back Hardcover, Round-back Hardcover, Case Binding (Diploma-style Hardcover)

Paperback 3 Options: :

- Standard Thread-sewn Paperback: Hot melt adhesive is applied to the spine in addition to sewing. This binding method limits the opening angle of the book, making it less suitable for writing and not easy to lay flat.

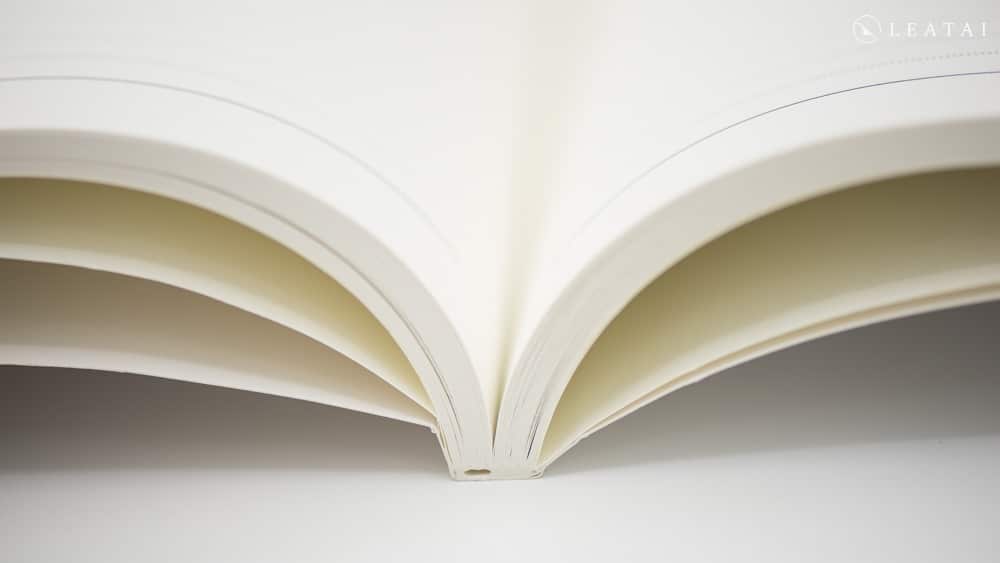

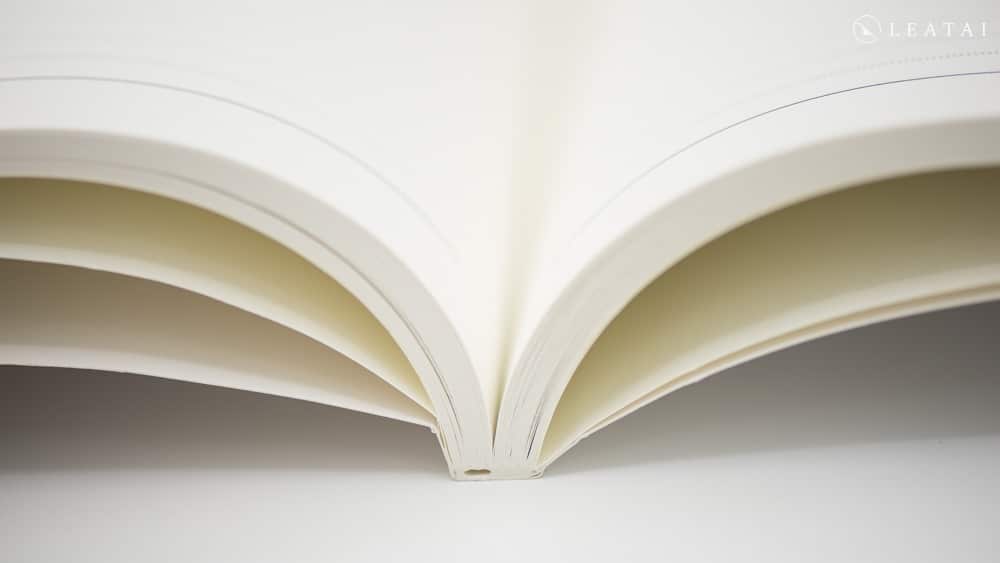

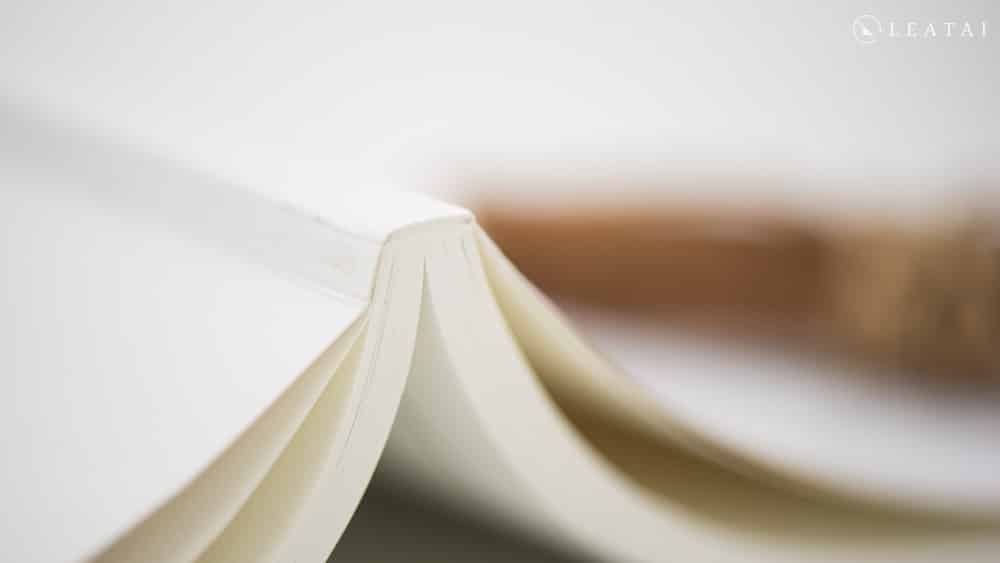

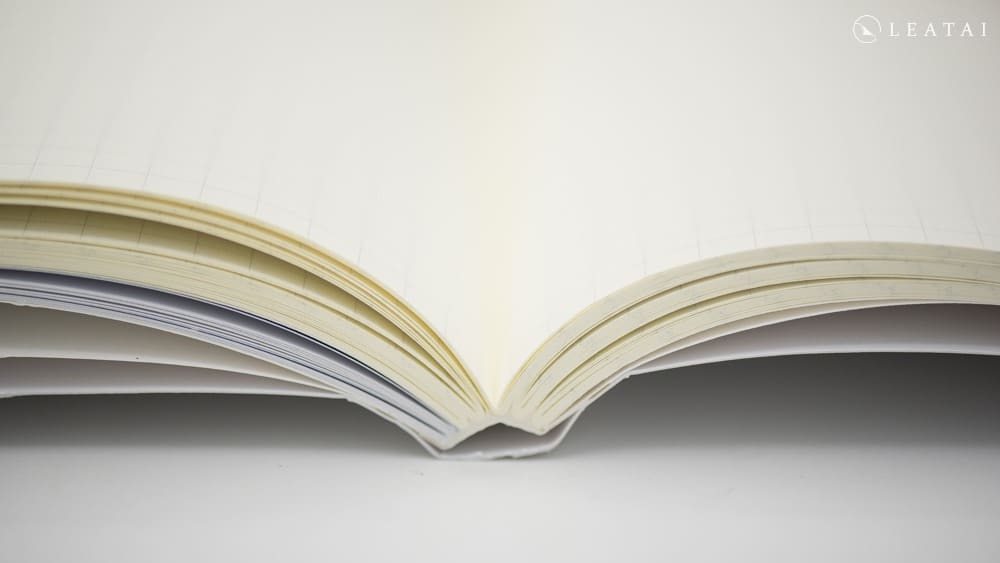

- Wide-open Thread-sewn Paperback: Besides sewing, a thin adhesive layer is applied to the spine. The binding area (spine) is not left bare; the outer pages are covered with slightly thicker paper as a cover. Although the spine is covered with paper, it is not bonded to the paper, maintaining a hollow state that facilitates laying the book flat.

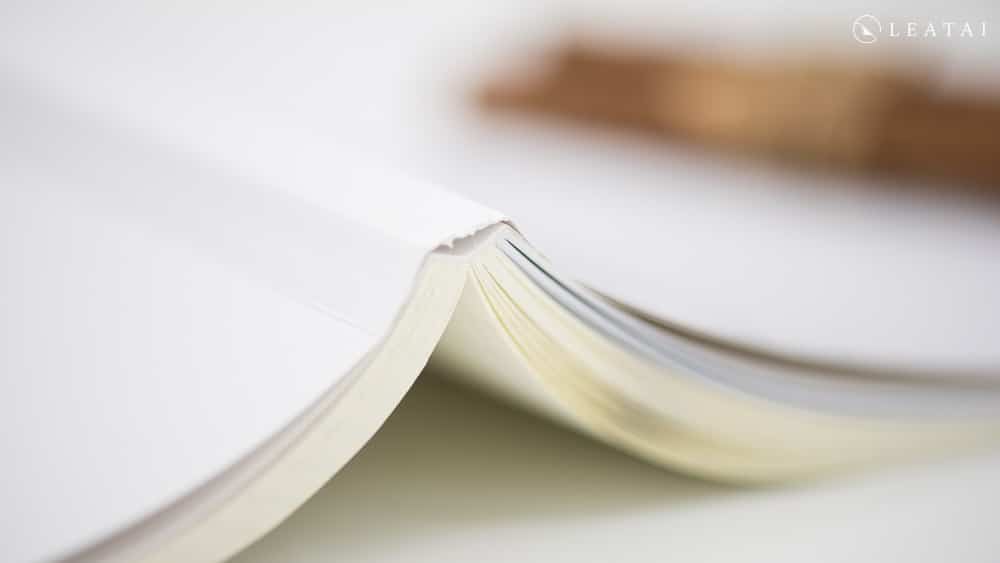

- Lay-flat Thread-sewn Paperback: Like other sewn bindings, the covers use heavier paper that is adhered to the front and back. The binding area (spine) is left uncovered (bareback binding), minimizing the pulling typically associated with covered spines like those seen in wide-open bindings. This design allows the pages to extend 180 degrees, achieving an utterly flat opening.

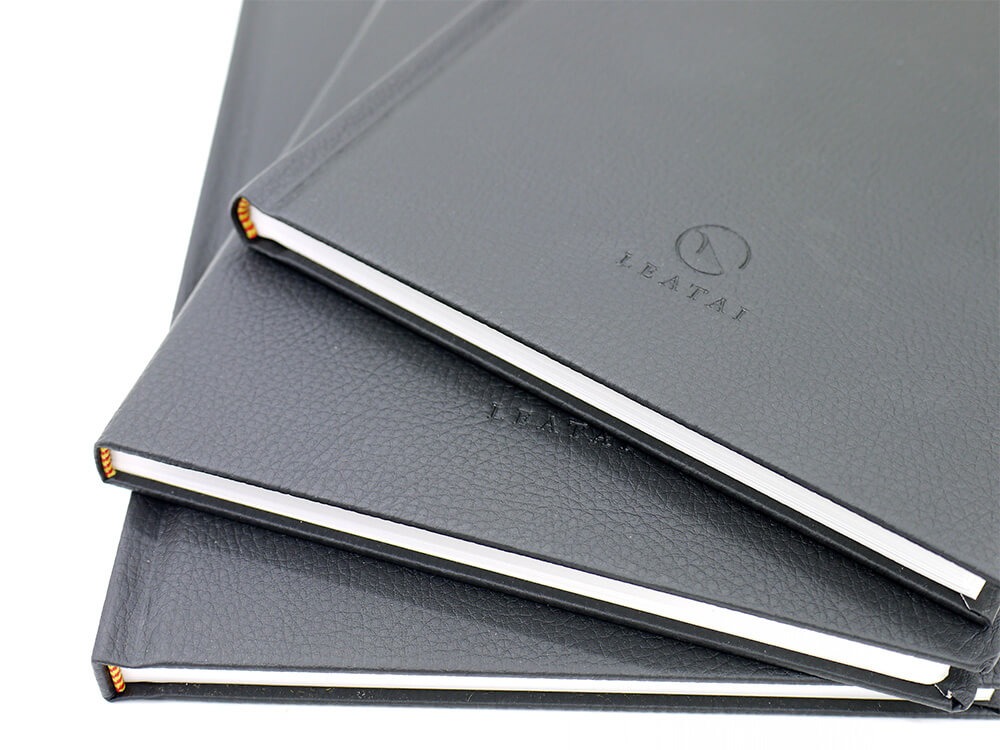

Hardcover Books :

Hardcover books utilize lighter-weight paper to cover the front, back, and spine (the middle strip of the book), which is wrapped around thick cardboard. This construction enhances the book’s durability and protective qualities.

The thickness of the cardboard can be chosen based on the book’s size requirements. Commonly used thicknesses are:

– B5 size(16K): Approximately 30 ounces

– A5 size(25K): Approximately 24 or 28 ounces

– 48K size: Typically around 24 ounces

These specifications ensure the book can withstand wear and tear while providing a sturdy and premium feel, making hardcovers suitable for high-quality publications and books for long-term use.

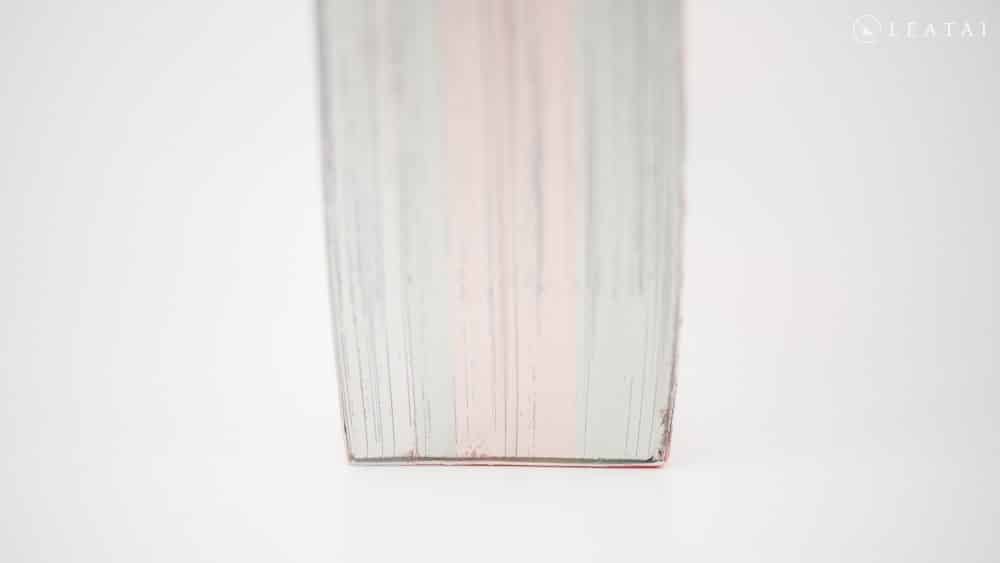

- Square-back Binding :

The book’s spine is square and flat, suitable for binding books with inner page thicknesses of less than 1.5 cm. This type features grooves pressed into the front and back covers near the spine to facilitate opening and closing. - Round-back Binding :

Different from square-back, round-back bindings do not include a cardboard strip in the spine. This is intended to create an arched shape, making it more suitable for thicker books over 1.5 cm in thickness. The use of tri-fold paper along the spine helps ideally present this curvature. Like the square-back, this style also includes grooves pressed at the front and back for easy opening. - Diploma-style Binding :

It is similar to a round-back in that it does not use a cardboard strip along the spine but differs in that it lacks the pressed grooves at the front and back, allowing for a visually seamless appearance. This style has recently become popular in book production due to its clean, uninterrupted look.

Book Binding Methods and Margin Design Explained

Margins:

The term “margins” refers to what is commonly known as the binding margin, located between the left and right pages. The size of the margins can vary depending on the binding method chosen. The primary purpose of these margins is to make the pages easier to read and prevent text from obscuring by the binding.

Threadless Perfect Binding: In threadless perfect binding, an additional 3mm is scraped off the spine to facilitate better glue adhesion. This results in a 3mm wider margin compared to thread-sewn binding methods. This ensures that the text near the spine is not lost in the fold when the book is opened, making it easier to read.

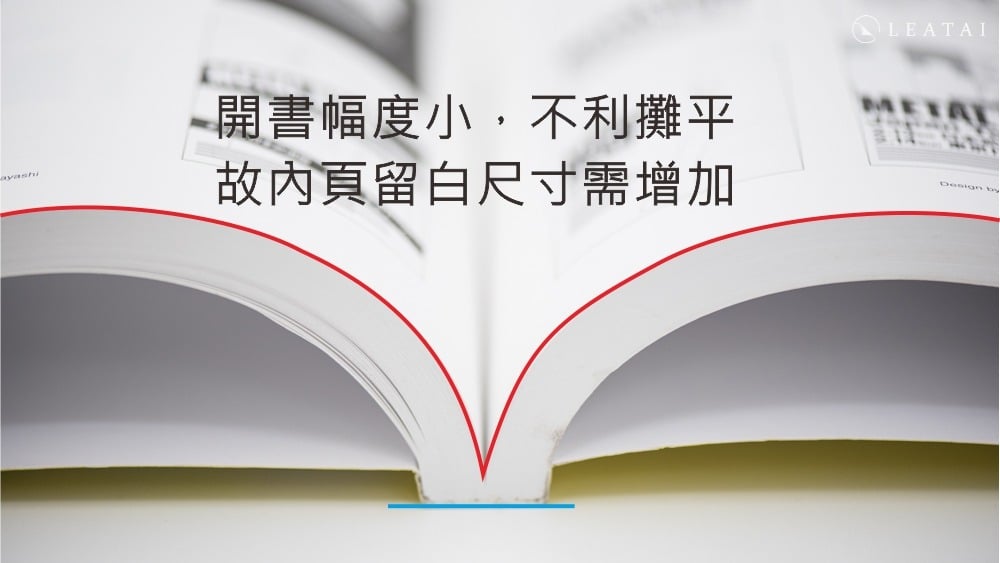

Traditional Perfect Binding:

Because this method uses a thick layer of adhesive on the spine, it restricts the book’s ability to open wide, making it difficult to lay flat. Therefore, the margin size, particularly the inner margin, must be increased to prevent text near the spine from obscuring when the book is opened.

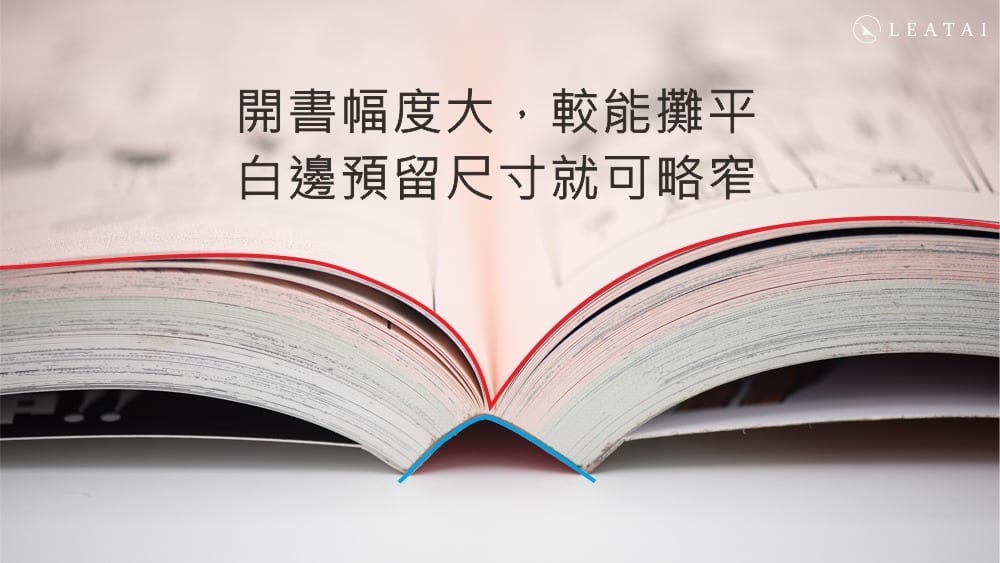

PUR Binding:

This binding method allows for a larger opening angle and can lay flat, meaning that the margins, especially the inner margins, can be narrower. The flexibility of PUR adhesive, which has higher tensile strength and better flexibility than traditional perfect binding glue, facilitates easier reading and handling.

Thread-sewn Binding:

In this method, the book’s spine does not require scraping off any paper, so the standard bleed is sufficient for binding. Thread-sewn binding enhances the durability and allows the book to open flat without needing wider margins, ensuring the text is not lost in the spine.

What Is a Paperback Book?

Paperback books are softcover books that use flexible, usually coated paper covers. The pages are typically glued together using a method known as perfect binding, making them lightweight and affordable. They’re commonly used for novels, planners, and catalogs.

What Is a Hardcover Book?

Hardcover books feature rigid covers made of thick cardboard, often wrapped with cloth, leather, or paper. They are usually case bound, making them more durable and ideal for premium journals, keepsake books, or long-term use.

Paperback vs Hardcover: Which Should You Choose?

If you’re customizing planners or journals for your brand, paperback may suit promotional items or travel journals, while hardcover fits premium editions or corporate gifts.

Common Types of Book Binding

Below are the most common book binding styles used in the industry:

Perfect Binding (Paperback Binding)

Pages are glued together at the spine and enclosed in a soft cover. Economical and widely used in paperback books, magazines, and planners.

Case Binding (Hardcover Binding)

Also called hardcover binding, this method involves sewing or gluing pages together and casing them in hard board covers. High durability, elegant appearance.

Spiral Binding

Uses a plastic or metal coil to bind pages. Allows full 360-degree rotation, ideal for notebooks, journals, and planners.

Saddle Stitch Binding

Pages are folded and stapled at the spine. Common for brochures, booklets, and slim notebooks with fewer pages.

Wire-O Binding

Similar to spiral binding, but uses double-loop wire for a more professional finish. Great for corporate notebooks or calendars.

Which Binding Is Best for Your Business?

At Leatai, we help businesses around the world choose the most suitable binding type for their custom notebooks and planners. Whether you need durable case binding for premium gifts or cost-effective perfect binding for bulk promotional use, our OEM experts can support you from design to delivery.

Common Bookbinding Issues

Bookbinding is a complex process involving multiple steps, and issues can arise at various stages. Here are some common problems that may occur during bookbinding:

- Incorrect Binding Order: A book’s pages should be bound in the correct sequence. An error in the binding order can result in a disorganized page arrangement, making the book problematic to read and navigate.

- Missing or Duplicate Pages: Pages may occasionally be omitted or duplicated during the printing or binding process. This issue often stems from errors in production or printing setups.

- Inconsistent Binding Tightness: The binding tightness of the pages within a book should be uniform. If some pages are bound too tightly or loosely, it can affect the overall aesthetics and quality of the book.

- Inconsistent Margin Sizes: If the margins of the book pages are conflicting, it can make the book appear untidy. This issue may occur if the bleed settings are not correctly configured during printing or binding. Additionally, even with correct bleed settings, slight variations in margins may still occur due to the tolerances introduced by the folding process; this is considered an acceptable margin of error.

These common issues highlight the need for careful quality control throughout the book production process, from printing to the final binding steps. Addressing these concerns helps ensure that the finished books meet the expected quality and usability standards.

FAQ

Q1: What is the difference between paperback and hardcover books?

A paperback has a soft, flexible cover, while a hardcover features a rigid, more durable cover. Paperbacks are lighter and more affordable, while hardcovers are sturdier and often used for higher-end products.

Q2: Which is more durable, hardcover or paperback?

Hardcover is more durable and long-lasting due to its solid cover and reinforced binding.

Q3: What are the types of book binding?

Common types include perfect binding, case binding, spiral binding, saddle stitching, and Wire-O binding.

Q4: Is spiral binding better than perfect binding?

Spiral binding offers flexibility and lay-flat usability, while perfect binding provides a cleaner spine and is more cost-effective for large print runs.

For more information, Leatai – a custom planner manufacturer in Taiwan